About this article

Categories

At Hot Screen, we make heat transfers around the clock – approximately 150,000 per day using so called screen print technology. This means our transfers are produced on large sheets and then cured in hot ovens, cut and mailed to you. However, it is to simplify a rather extensive process. There is a lot more work behind our products, not least quality checks, mixing of special colours, maximizing the number of transfers per sheet to reduce waste, purify our process water. When we make heat transfers it can almost be called a craft, although it is an industry.

We make heat transfer in a fast pace – Hot Screen is like a well-oiled machine! Each department has its own workflow, and each department moves your order forward in the making of the heat transfer. With a production time of a maximum of 5 working days we are also one of the fastest players in the industry, and we can be even faster: if you choose one of our express options, we can produce your order the same day and ship the day after.

Approximately 70% of our customers order their heat transfer online in our webshop. If you choose to place your order by email or phone, you get in touch with our sales support.

When the proof is ready and approved, it is sent to the Digital Pre Press department, which ensures that the proof has the right characteristics for the making of the heat transfer. We also fit the transfers onto our print sheets to maximize the space and reduce waste.

When the print sheets are ready, our frames can be developed for the print job. This happens almost automatically in various machines, with almost no manual handling. We check the frames before the making of heat transfer – we have checks at every step. After this, we pick up the correct colours, or mix new ones if necessary, and move frames and paint ahead to Production.

Things go fast here! Our machines run hot day and night in three shifts.

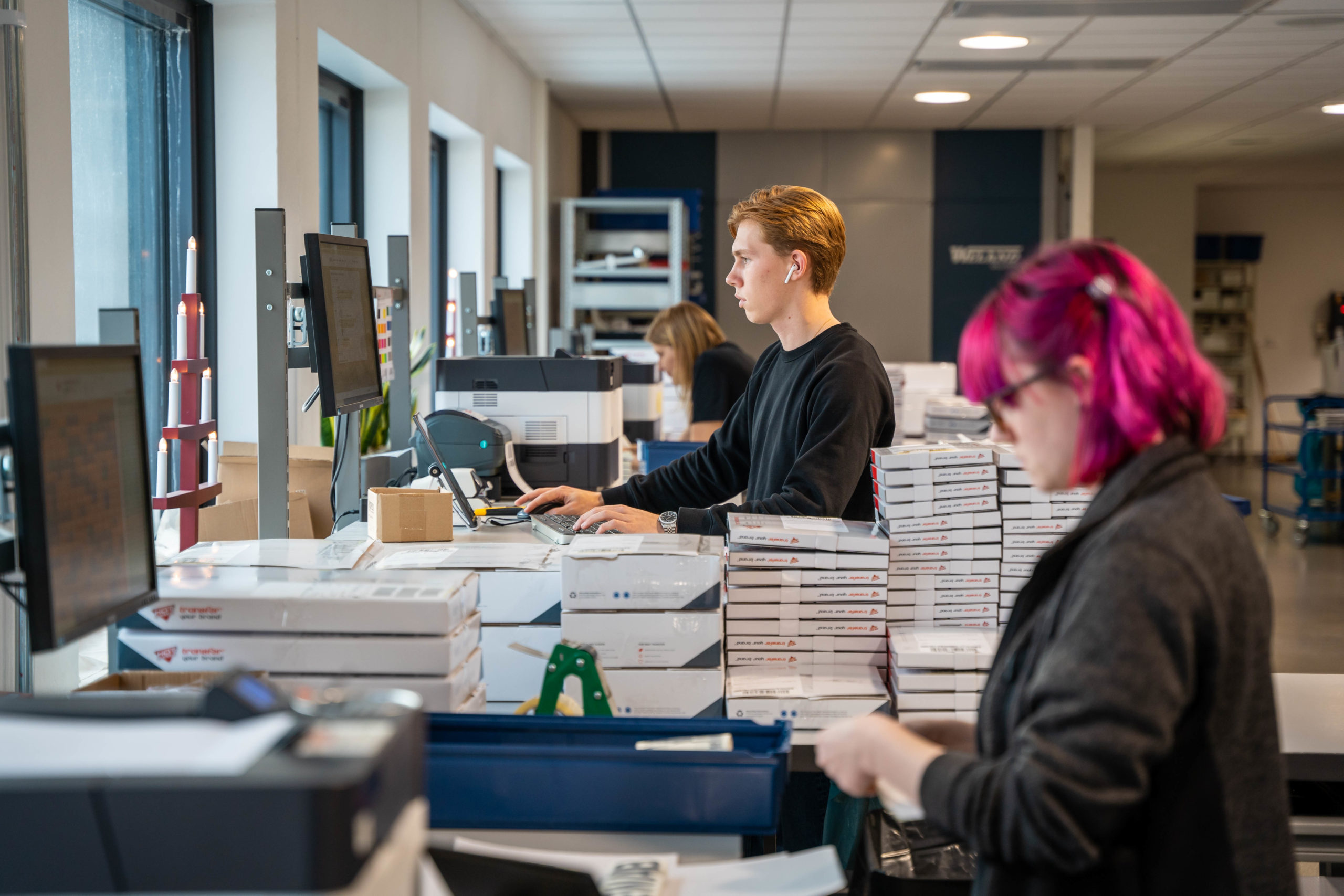

After the printing department, zealous scrutiny awaits at the Quality department. We cut up each order/logo and pack as many orders together as possible before sending them off.

In every step of making heat transfers we focus on quality, waste, environment, economy, sustainability and efficiency. That spirit is present in every department, between every department, and results in a product that is durable, environmentally certified and with a long life span. You can also store it for at least 5 years.

We make heat transfers according to your order , or you can choose from our ready-made heat transfers. To place an order, the best is to apply for an account in our webshop. Then you log in and get access to our tool, which contains all the functions you need to create your own proofs. In the webshop you will also find our ready-made heat transfers, for example numbers, flags and useful words such as Supervisor and Visitor.

About this article

Written by:

Christin

Categories

Related articles

Sustainable Prints on Workwear

Read more

This is how you use our plotter transfer

Read more

Club clothing with a sustainable print

Read more

Heat Press Hot 2000 troubleshooting

Read more

About this article

Written by:

Christin

Categories

Related articles

Sustainable Prints on Workwear

Read more

This is how you use our plotter transfer

Read more

Club clothing with a sustainable print

Read more

Heat Press Hot 2000 troubleshooting

Read more

Prints on workwear? Choose the heat transfer Stark!

Products

Tips & Tricks

The plotter print is a variation of our product Stark Heat Transfer.

Products

Learn more about the various print methods in the textile industry.

Print methods

Mon-Thu: 08.00-16.30

Fri: 08.00-15.30

Följ oss!

When you archive an article, it disappears from your webshop and is no longer orderable.

When you activate an article, it disappears from your archive and you can order it again