We offer pneumatic and electric heat presses. You have three models to choose from, each one with unique properties but the same quality, usability, performance, safety and durability. Below is an overview of our presses and a brief summary of their properties.

Our all-electric press is easy to use and suitable for small production runs. The machine uses a safe two-handed grip and is ergonomically designed.

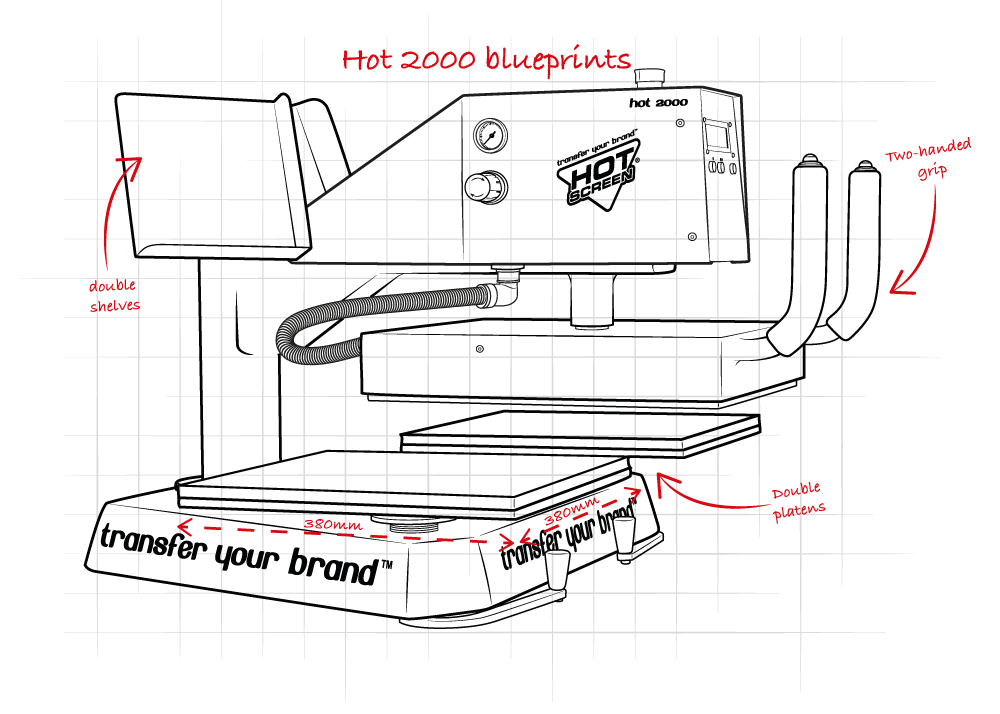

The best-selling favourite press! A powerful, ergonomic unit with two bottom plates and easy manoeuvring that quickly scales up to a safe and efficient workflow.

Our high volume application press. The machine has four bottom plates, and a heating and cooling plate, and uses a special carousel design intended for efficient, industrial heating with great ergonomics.

Heat presses are used to heat and simultaneously apply heat transfers to garments. They are an important part of the process, and if you want good results you need a unit with stable heat and guaranteed application force. This is why we design and manufacture our presses ourselves, in Sweden and using Swedish steel. We use our presses for product testing and measurements in order to ensure that the transfers are applied correctly and under optimal circumstances. This means they will last for the lifetime of the garment, despite wear and tear, washing and drying. Product development, production and service are done in our workshop in Kinna, an hour by car from our subsidiary transfer printing works in Fjärås.

Garment processing puts the emphasis on speed. Each order is unique with changing requirements, regardless of whether it is for training gear prints or applying a logo to work clothes. Our heat presses can be supplemented by a number of accessories in order to facilitate your work. You can find all of our accessories by logging into the webshop.

Our cross laser for the Hot 2000 is a perfect example, and it enables the user to place the print in exactly the same space on every garment. We also offer different bottom plates for different types of garment, including a bottom plate with grooves for tops with zippers and buttons.

The partnership with our subsidiary was initiated in 2015 when they were tasked with developing a heating press for industrial use (Hot 4000), and a professional performance heating press (Hot 2000). The partnership continued to intensify until Hot Screen acquired the company in 2019. The production takes place on the same premises where it all began using Swedish steel and focusing on sustainability and quality.

Our heat presses have a long service life and are very durable. If they are under heavy load for a long time, they may require service – which also takes place at our facility in Kinna. We offer quick responses as well as the possibility to borrow a press while we have yours in for service – all to avoid downtime. Our service team is always available to provide advice and ensure that production resumes quickly.

Our webstore offers both heat presses, accessories and transfers. You can also contact our sales support if you have any question. If you already own one of our presses and it needs to be serviced, you can book an appointment with our service technician, visit our contact page!

A heat press is a machine that bonds materials using temperature, pressure and time. They are mainly used for textile processing and is available in different models, such as manual, semi-automatic, membrane, pneumatic or large format presses.

Manual presses require the user’s force, while semi-automatic presses automatically open after a preset time. Pneumatic presses require no effort and also open automatically, but require a compressor to generate compressed air. Electric presses operate solely on electricity and do not need a compressor, but otherwise function like pneumatic presses in terms of automation.

Hot Screen’s heat presses are only suitable for textile printing. However, there are heat presses that can be used on other materials such as wood, leather or plastic. Heat presses can also be used to bond different materials to each other using pressure, time and temperature.

The weight of the heat press varies depending on its type and size. Hot Screen offers light presses at around 80 to 100 kg as well as heavier models weighing up to 300 kg.

The temperature of the heat press varies depending on the settings and the specific requirements of the heat press: Strong, Flex or Reflex. We recommend a temperature of 130 oC – 160 oC. Generally speaking, Hot Screens presses can reach temperatures of over 200 oC.

We have heat presses in the following sizes: Hot 1000e 64x52x71/112 cm, Hot 2000 100x64x83 cm and Hot 4000 150 cm. The presses are supplied with a selection of replaceable bottom plates that can be adapted to the textile. The Hot 1000e model is delivered with bottom plates in the size 38×38 cm and 15×15 cm. The Hot 2000 model is supplied with double bottom plates in size 38×38 cm with fabric covers and individual bottom plates in size 38×15 cm, 15×15 cm and 15×10 cm. The Hot 4000 model, on the other hand, has four bottom plates of 38×38 cm in a carousel solution that rotates. Our presses are suitable for everyone from beginners to professional, industrial users. If we take a look at the market, there are other small presses for specific items like hats or mugs, and large presses for items like banners or blankets.

If you decide to use one of our presses you will receive a reliable machine with high performance, and access to numerous features that ensure perfect results every time.

Over the years, we have accumulated plenty of knowledge on how best to process garments using our heat presses, also known as heat presses. If you want advice on how to improve your ergonomics and workflow, suitable accessories etc., read more here. You can also read more in our print guide, where we have gathered all of our knowledge.

Mon-Thu: 08.00-16.30

Fri: 08.00-15.30

Följ oss!

When you archive an article, it disappears from your webshop and is no longer orderable.

When you activate an article, it disappears from your archive and you can order it again